The Absolute Maximum,

at a Complete Minimum.

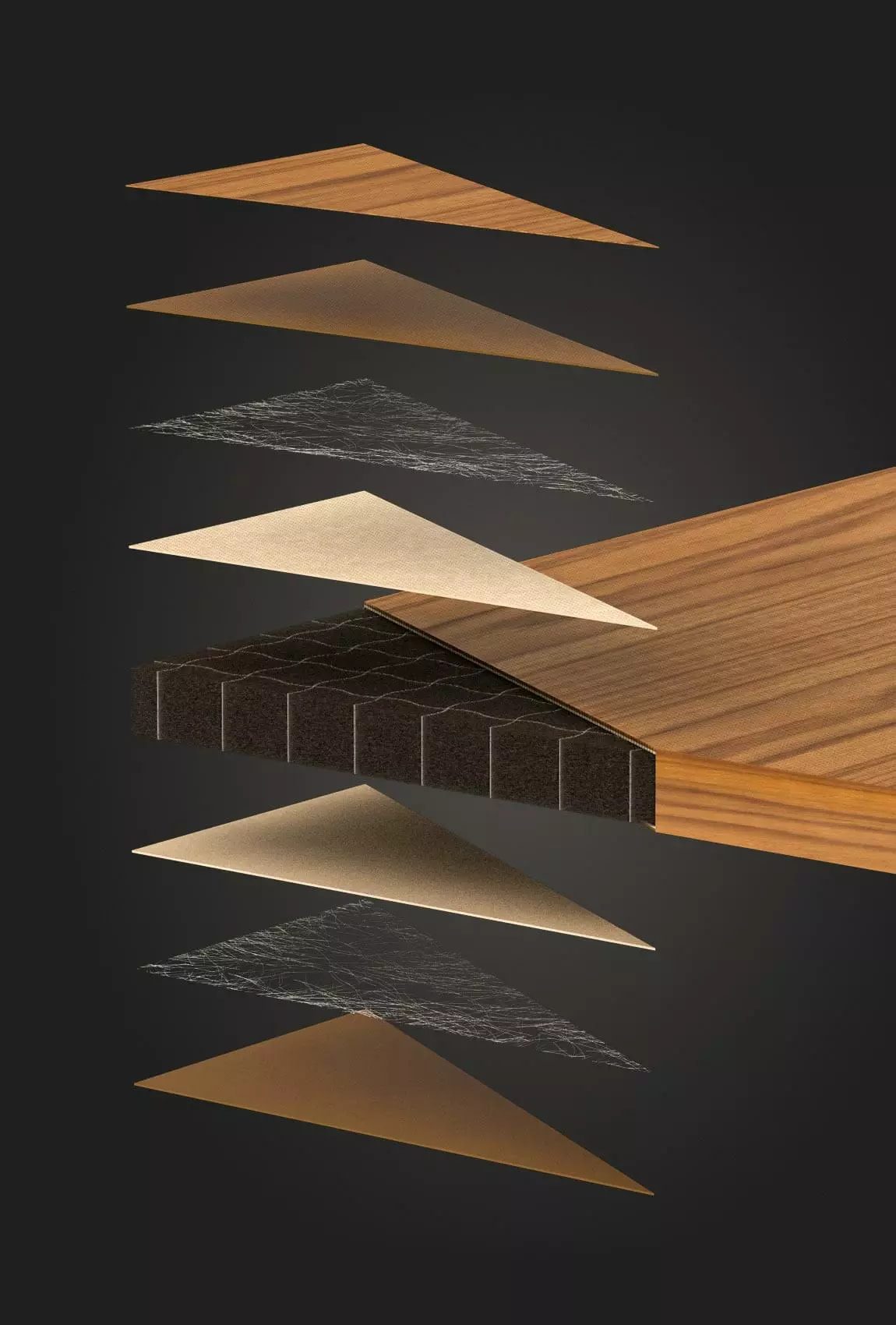

The SoundPly RF series are the world’s most advanced acoustic panels, providing a level of sound absorption never before achieved in a solution so compact and versatile. Demonstrating an unrivaled degree of performance, RF panels are the unequivocal choice for the most acoustically demanding environments.

SoundPly RF panels unlock new possibilities for fundamentally better ways to address environmental noise control, recasting the entire concept of how acoustic panels can be used.

MORE THAN INCREMENTAL.

The RF series was born from a zero-compromise pursuit for acoustic perfection. When challenging our top engineers with the question “How do we develop the world’s most effective acoustic panel?”, the RF series was their silent —and highly sound-absorbent— reply.

Compared with traditional acoustic panels, RF panels absorb more sound using better methods, in the most efficient way… but these panels do more than just absorb sound.